Contact us

ALUSTEP® FN is a lightweight sandwich panel with a core in aramid paper and skins in glass fibre reinforced with phenolic resin.This panel offers unique characteristics since it combines lightweight with high mechanical properties. Thanks to the low flammability of phenolic resin, the certified version of this panel can be used in shipyards, trains and transport in general.

|

A - SKINS IN GLASS FIBRE FABRIC impregnated with phenolic resin Thickness mm: 0,25÷0,3

B - CORE IN ARAMID PAPER HONEYCOMB

|

X1 = other diameters on request

TECHNICAL FEATURES

Technical data sheet for standard panels (dimensions, materials and special finishes on request) |

|||||||

TECHNICAL CHARACTERISTICS OF PANEL |

|||||||

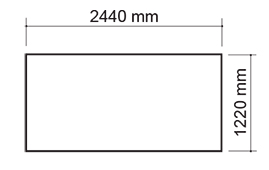

panel size mm |

standard 1250 x 2500 |

||||||

thickness’ tolerance mm |

± 0,4 |

||||||

dimension’s tolerance mm |

± 30 |

||||||

skins’ thickness mm |

0,3 |

||||||

glass fibre skin type |

satin 8/1 300 gr/m² |

||||||

Impregnation |

phenolic resin |

||||||

honeycomb type |

aramid paper, impregnated with phenolic resin |

||||||

diameter of honeycomb Ø = mm |

from 3 to 4,8 |

||||||

honeycomb density Kg/m³ |

48 and 32 |

||||||

adhesive for aluminum honeycomb |

thermoplastic |

||||||

PANEL PHYSICAL AND MECHANICAL PERFORMANCES |

|||||||

type panel (some examples) mm |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

panel weight ‡ Kg/m2 |

1,4±0,1 |

1,7±0,1 |

1,9±0,1 |

2,1±0,1 |

2,4±0,1 |

2,6±0,1 |

2,8±0,1 |

compressive stabilised strength MPa ** ‡ ASTM C 365-365 M Mpa |

1,6 ± 0,2 |

||||||

maximum load ** ‡ ASTM C 393 † N |

100±10 |

210±20 |

320±30 |

430±40 |

540±50 |

650±60 |

740±70 |

deflection at maximum load ‡ ASTM C 393 † mm |

49+5 |

24±3 |

16±2 |

12±1 |

10±1 |

8±1 |

7±1 |

skins E Elastic Modulus ** Mpa |

22.000±1.000 |

||||||

moment of inertia I ** mm4/m |

3.300 |

14.120 |

32.400 |

58.200 |

91.600 |

132.000 |

181.000 |

middle resistance to peeling ** ‡ ASTM D1781-98 (2012) |

> 450 N/76 mm or >45 Nmm/mm |

||||||

maximum service temperature ** °C |

- 50 / + 80 |

||||||

thermal expansion coefficient ** °C-1 |

1,5 * 10^-5 / 1,5 mm for ΔT 100 °C for 1 meter length |

||||||

** Tested by Internal Laboratory

*** Approximate value

† Sample dimension with 4 support points (L, W) 540x540; distance among the lower points 500mm, distance among the upper points 250mm

‡ All values refer to a panel made of a honeycomb in nomex diameter 3mm mm 48 kg/m3 and two skins in fibreglass impregnated with phenolic resin and thermoplastic adhesive

Certified version of ALUSTEP FN must be requested while asking for a quotation.

Certified products must be requested in advance and might have a price surcharge due to certified materials.

Certifications/Classifications for ALUSTEP FN’s reaction to fire Tested by a certified institute

| FIRE REACTION | |||

| SECTOR | NORM | CLASSIFICATION | DESCRIPTION |

|

SHIPBUILDING |

FTP CODE 2010 3.18a

0407 |

LOW FLAMESPREAD MOD. B. Certification Nr.

Certification Nr.

|

ALUSTEP FN

Aramid paper honeycomb panel with

|

|

|

U.S. Coast Guard |

MOD. B. USCG Approbation Nr.

|

ALUSTEP FN Aramid paper panel with

|

|

RAILWAY |

UNI EN 45545-2 |

HL2 (HAZARD LEVEL)

|

ALUSTEP FN Aramid paper panel with skins

Meets requirements for applications R2 suspended ceilings, countertop R1 partitions |

| RAILWAY VEHICLES |

UNI EN 45545-2 |

HL3 (HAZARD LEVEL) Class certification Nr.

|

ALUSTEP FN aramid paper panel with skins in Meets requirements for applications

|

Honeycomb core’s properties |

|||||

|

Nomenclature |

Compression Strength |

L-Shear |

W-Shear |

||

| Cell size mm | Density kg/m3 | N/mm2 | N/mm2 | N/mm2 | |

|

Hexagonal |

3,2 |

48 |

1,90 |

1,16 |

0,62 |

|

Hexagonal |

3,2 |

64 |

3,10 |

1,48 |

0,82 |

|

Hexagonal |

3,2 |

80 |

4,70 |

1,95 |

1,05 |

|

Hexagonal |

3,2 |

96 |

6,60 |

2,45 |

1,42 |

|

Hexagonal |

3,2 |

128 |

11,30 |

2,95 |

1,78 |

|

Hexagonal |

3,2 |

144 |

13,20 |

3,05 |

1,90 |

|

Hexagonal |

4,0 |

29 |

0,60 |

0,45 |

0,26 |

|

Hexagonal |

4,0 |

80 |

5,10 |

1,90 |

0,98 |

|

Hexagonal |

4,8 |

32 |

0,90 |

0,58 |

0,36 |

|

Hexagonal |

4,8 |

48 |

2,60 |

0,98 |

0,56 |

|

Hexagonal |

4,8 |

64 |

3,40 |

1,70 |

0,92 |

|

Hexagonal |

4,8 |

80 |

6,00 |

1,95 |

1,10 |

|

Hexagonal |

4,8 |

96 |

7,30 |

2,26 |

1,32 |

|

Hexagonal |

6,4 |

24 |

0,54 |

0,34 |

0,18 |

|

Hexagonal |

6,4 |

32 |

0,80 |

0,54 |

0,30 |

|

Hexagonal |

6,4 |

48 |

2,05 |

1,00 |

0,56 |

|

Hexagonal |

6,4 |

64 |

3,40 |

1,54 |

0,79 |

|

Hexagonal |

9,6 |

24 |

0,54 |

0,34 |

0,18 |

|

Hexagonal |

9,6 |

32 |

0,68 |

0,56 |

0,29 |

|

Hexagonal |

9,6 |

48 |

1,80 |

1,15 |

0,66 |

|

Over expanded |

4,8 |

29 |

0,60 |

0,31 |

0,32 |

|

Over expanded |

4,8 |

48 |

2,30 |

0,60 |

0,72 |

|

Over expanded |

4,8 |

64 |

3,80 |

0,72 |

0,90 |

|

Over expanded |

4,8 |

72 |

4,00 |

0,75 |

0,92 |

|

Over expanded |

4,8 |

80 |

5,30 |

0,88 |

1,17 |

|

Over expanded |

4,8 |

96 |

6,70 |

0,92 |

1,28 |

|

Over expanded |

6,4 |

48 |

2,30 |

0,60 |

0,72 |

|

Over expanded |

6,4 |

64 |

3,20 |

0,72 |

0,90 |

Tolerance - density +/- 16%

STANDARD DIMENSIONS (other dimensions available on request)

LIABILITY DISCLAIMER: The above data are to the best of our knowledge correct and are intended to give information about our products and their potential applications. No warranty is given or implied in respect of certain properties of the products or their suitability for a particular application. We reserve the right for technical changes without further notice. We guarantee impeccable product quality under our terms of sale.